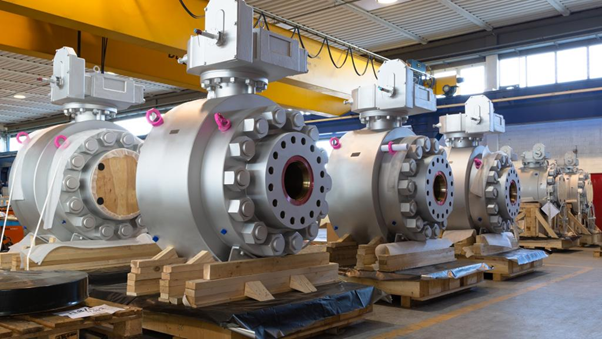

Industrial Ball Valves: Applications, Selection, and Maintenance Tips

Industrial ball valves are essential components in various industries, providing precise control over fluid and gas flow. In this informative guide, we will delve into the world of industrial ball valves, exploring their applications, the factors to consider when selecting the right valve, and valuable maintenance tips to ensure their longevity.

Applications of Industrial Ball Valves

Industrial ball valves find extensive use across a wide range of applications due to their versatility and reliability. Here are some key industries where these valves play a crucial role:

Oil and Gas Industry

Ball valves are commonly used in pipelines, wellheads, and production facilities to control the flow of oil and gas. Their ability to withstand high pressures and harsh environments makes them ideal for these applications.

Chemical Processing

In the chemical industry, where the handling of corrosive and abrasive fluids is common, ball valves are preferred for their resistance to corrosion. They help manage the flow of various chemicals safely and efficiently.

Water Treatment

Ball valves are essential in water treatment plants and distribution systems, ensuring precise control over the flow of water, chemicals, and wastewater.

HVAC Systems

Heating, ventilation, and air conditioning systems rely on ball valves for temperature and fluid control. Their quick operation and tight sealing make them suitable for HVAC applications.

Food and Beverage Industry

In the food and beverage sector, ball valves are used to control the flow of liquids, sauces, and beverages. Their sanitary design ensures compliance with hygiene standards.

Selecting the Right Industrial Ball Valve

Choosing the right industrial ball valve is crucial to ensure optimal performance and safety in your specific application. Consider the following factors when making your selection:

1. Material

Select a valve made from a material that is compatible with the fluids and operating conditions of your application. Common materials include stainless steel, brass, and PVC.

2. Size

Choose the appropriate valve size based on the flow rate and system pressure requirements. Proper sizing prevents flow restrictions or excessive pressure drops.

3. End Connections

Consider the type of end connections needed for your installation, such as threaded, flanged, or welded connections. The choice depends on your system’s configuration.

4. Pressure Rating

Check the pressure rating of the valve to ensure it can handle the maximum pressure in your system without leakage or failure.

5. Actuation

Determine whether manual or automated (actuated) valves are required for your application. Automated ball valves are used in systems that require remote or precise control.

Maintenance Tips for Industrial Ball Valves

Proper maintenance is essential to extend the life of industrial ball valves and ensure their continued reliability. Here are some maintenance tips to consider:

Regularly inspect the valve for signs of leakage, corrosion, or damage.

Lubricate the valve’s moving parts as recommended by the manufacturer.

Clean the valve to remove any debris or buildup that may affect its operation.

Replace worn-out seals or gaskets to maintain a tight seal.

Perform routine operational checks to ensure the valve opens and closes smoothly.

Industrial Valve Manufacturer and Ball Valve Suppliers

When sourcing industrial ball valves, it’s essential to collaborate with reputable manufacturers and suppliers. They can provide guidance, product support, and a range of options to meet your specific needs. Whether you are looking for a custom solution or standard valves, working with trusted ball valve suppliers is key to a successful procurement process.

In conclusion, industrial ball valves are integral components in various industries, offering precise control and reliability. Understanding their applications, selecting the right valve, and implementing proper maintenance practices are crucial for optimal performance and system longevity. By partnering with reliable industrial valve manufacturers and suppliers, you can ensure that you have access to high-quality valves that meet your industry’s specific requirements.